A NSW manufacturing landscape enhanced by GME

Manufacturer's Monthly

DECEMBER 18, 2024

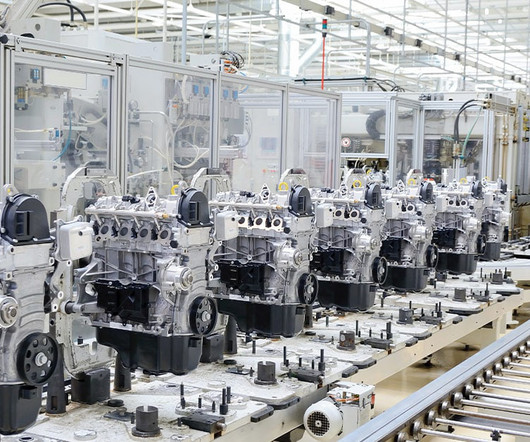

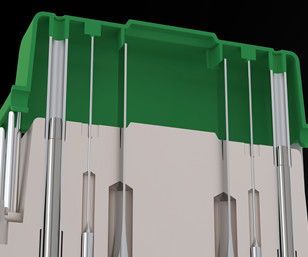

Images: GME GME manufactures UHF CB radios and emergency beacon products, exemplifying its commitment to local production and innovation in the Australian manufacturing industry. This transformative approach aligns with the governments commitment to fostering a robust manufacturing sector, ultimately benefiting communities across NSW.

Let's personalize your content