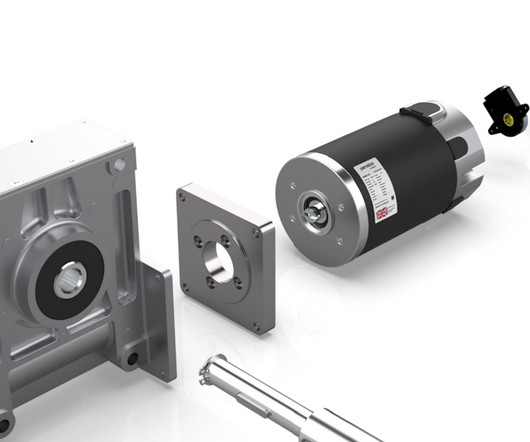

Modular motors and gearboxes make product development simple

Robotics Business Review

DECEMBER 23, 2024

To beat the competition, engineers must shrink development times, optimize product performance and traverse an ever-growing number of supply chain issues. This has made it a challenge to source parts for physical prototyping especially electric motor and motion systems. Sponsored by Parvalux by maxon.

Let's personalize your content