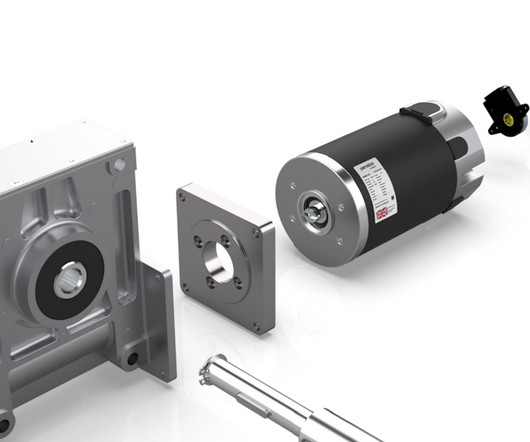

ElectroCraft expands Ann Arbor facility to strengthen U.S. manufacturing

Design World

FEBRUARY 7, 2025

manufacturing capacity, minimizing dependence on global supply chains, and improving lead times for customers. manufacturing appeared first on Design World. manufacturing appeared first on Design World. ElectroCraft has announced the expansion of its Ann Arbor, MI facility.

Let's personalize your content