igus acquires Atronia, invests in smart plastics sensors for Industry 4.0

Robotics Business Review

JUNE 13, 2024

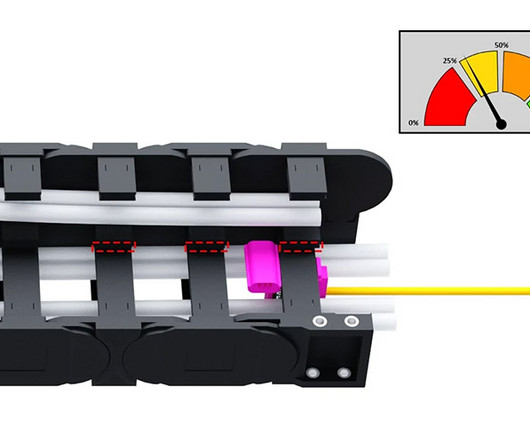

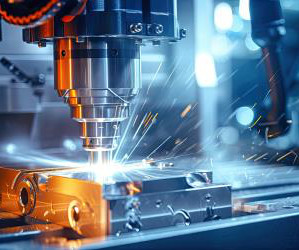

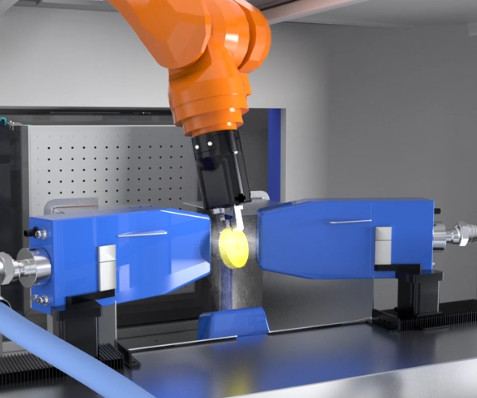

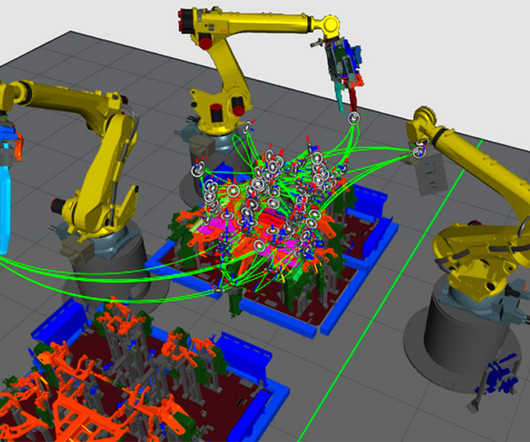

Source: igus The combination of sensing with motion plastics, which eliminate the need for lubricants, promises easier-to-maintain machinery for Industry 4.0. Industry 4.0 demands mass production of critical sensors Industry 4.0 This allows us to start series manufacturing for the Industry 4.0

Let's personalize your content