Industry 4.0 Club Announces Strategic Leadership Changes

Gary Mintchell

JANUARY 12, 2024

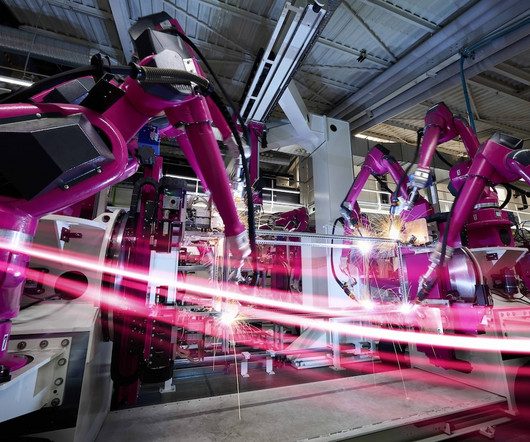

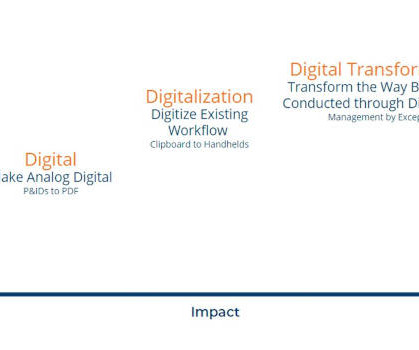

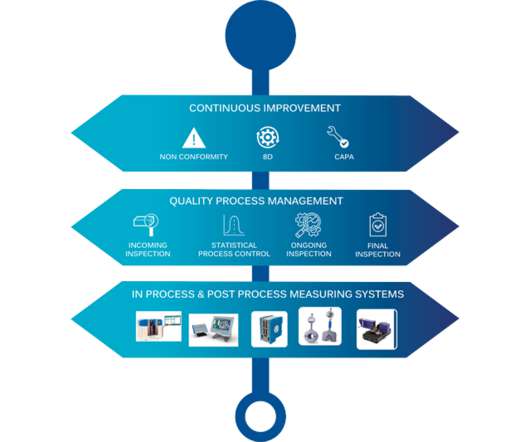

You may look at the headline and wonder “Industry 4.0 The Industry 4.0 Club is building a community to give encouragement and ideas to small-to-medium sized manufacturers who need/want to adopt modern Industry 4.0 The Industry 4.0 From their press release: The Industry 4.0

Let's personalize your content