Welding project uses robotics to crunch 12 workhours into 45 minutes

Robotics Business Review

JUNE 14, 2025

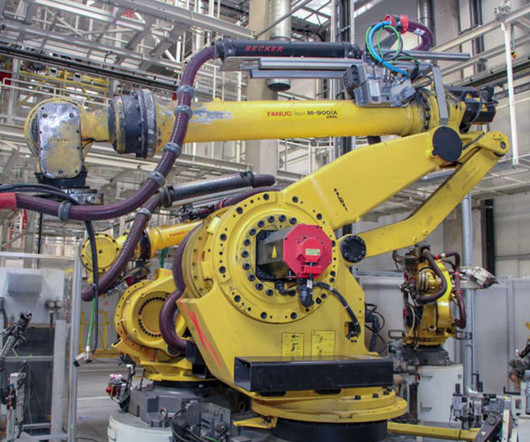

Figure 1: The fully automated robotic welding work cell, with all actions orchestrated by an AutomationDirect Productivity PLC, synchronizes the welding process, robot movements, and fixture positioning. Synchronization of motion with the gantry positioning system for the robotic welding arm was a core requirement to the design.

Let's personalize your content