Caron Engineering Automation Solutions Improve Process Control

Modern Machine Shop

AUGUST 13, 2024

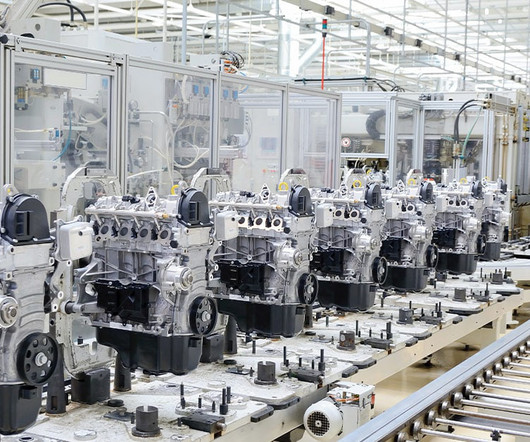

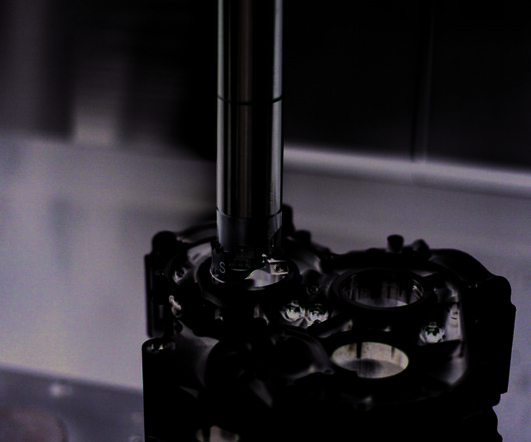

Caron Engineering showcases its latest technology for automation, tool monitoring and process control. Source: Caron Engineering Inc.

This site uses cookies to improve your experience. To help us insure we adhere to various privacy regulations, please select your country/region of residence. If you do not select a country, we will assume you are from the United States. Select your Cookie Settings or view our Privacy Policy and Terms of Use.

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

Used for the proper function of the website

Used for monitoring website traffic and interactions

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

Modern Machine Shop

AUGUST 13, 2024

Caron Engineering showcases its latest technology for automation, tool monitoring and process control. Source: Caron Engineering Inc.

Mold Making Technology

NOVEMBER 26, 2024

Acceleration/deceleration time may be reduced as a result of a compact integral spindle, contributing to improved cycle times and surface finishes. This large-capacity VMC can accommodate up to a 5,500-pound table load with 17 inches between columns. Smaller and mid-range machines are available.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Fabricating & Metal Work

JULY 6, 2024

RN35 includes feed rate optimization, ensuring improved cycle time and increased productivity. By enabling faster cycle times and enhancing tool performance, manufacturers can drive up their profits effectively. RN35 includes feed rate optimization, ensuring improved cycle time and increased productivity.

Robotics Business Review

JANUARY 17, 2024

In addition, the integration offers closed-loop feedback to the robot for autonomous process control, it said. Environments that require rapid and accurate processing like semiconductor and electronics operations also benefit substantially,” he said. Kniptash, FOBA’s sales manager for Americas.

Gary Mintchell

SEPTEMBER 27, 2023

From the CAM system, machine-specific G-code programs are sent to its NCSIMUL software, which incorporates the entire machining environment to generate a digital twin of the machinery, part, and processes for cycle-time optimisation, set-up revision, and program certification.

Control Engineering

SEPTEMBER 6, 2022

Rekha recently took on a technical project leadership role, driving ISA88: Batch Control in projects, and has been a valuable resource ensuring the best quality of product for customers. She is a well-respected process control and safety-certified engineer that leads by example and mentors other engineers to fulfill their potential.

Fabricating & Metal Work

FEBRUARY 14, 2023

Top-tier companies manufacture a variety of resistance welding capabilities in their product lines that provide optimal performance, versatility and short cycle times, and numerous other advantages. The IS-Q series offers control monitoring with both MG3 and the OP-AWS3-A Active Welding Systems.

Modern Machine Shop

FEBRUARY 18, 2025

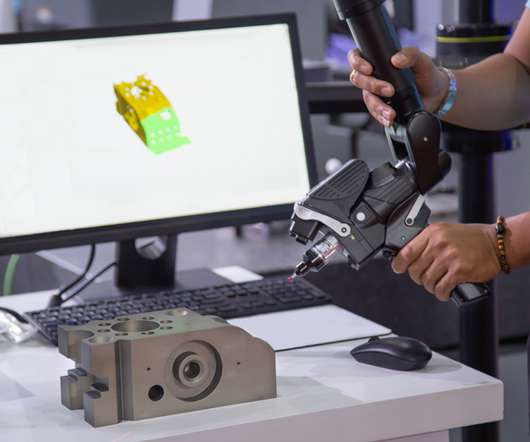

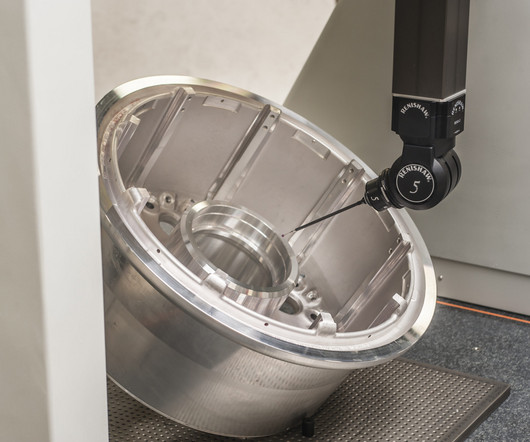

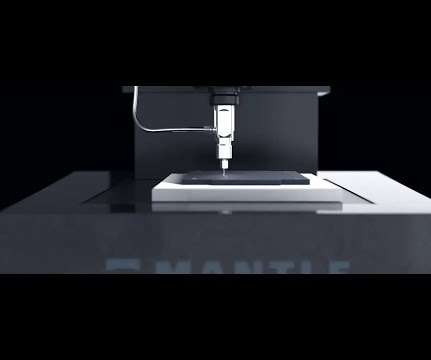

The result is reduced cycle times, improved productivity and increased throughput. Introducing flexible gaging close to the point of manufacture also enables the validation of discrete machining operations, enabling automated process control and tool offset management.

Fabricating & Metal Work

FEBRUARY 17, 2023

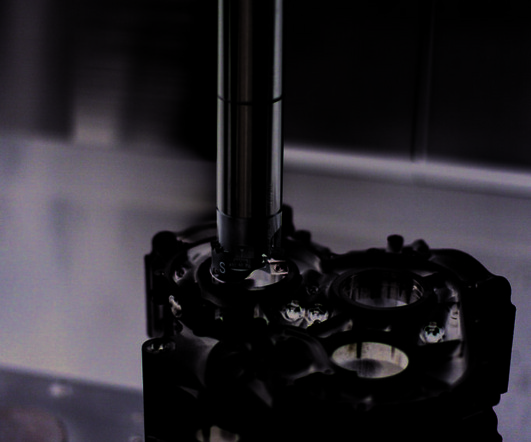

To ensure aerospace and medical part processing security, the CERATIZIT ToolScope monitoring and control system consists of a suite of specialized modules – process control, machine protection and digitization and documentation – aimed at measuring and optimizing particular aspects of machining operations.

Gary Mintchell

SEPTEMBER 22, 2022

Deacom (ECI Software)—With a deep awareness of the challenges faced by process manufacturers and distributors, Deacom has been developed as an ERP solution tailored to the needs of medium-sized enterprises within industries such as Food & Beverage, Chemical and Coatings, Cosmetics, Pharmaceuticals, and Nutraceuticals to name a few.

Mold Making Technology

MAY 11, 2023

Photo Credit: Netzsch Process Intelligence GmbH The sensXPERT Digital Mold is a process control solution from Netzsch Process Intelligence GmbH to reach government and environmental sustainability practice goals in relation to resource-saving, circular plastics processing. The SensXpert Digital Mold flow.

Fabricating & Metal Work

JANUARY 7, 2024

These include analyzing processes and providing recommendations for cutting tool selection and cycle time reduction; conducting maintenance and operation training; diagnosing and repairing machines; troubleshooting software issues; and recommending part repair and replacement schedules.

i4.0 today

JANUARY 8, 2024

The IS-Q Series offers control monitoring with both MG3 and the OP-AWS3-A Active Welding Systems. The OP-AWS3-A integrates the process control of all mechanical and electrical parameters. The integrated process monitoring offered by this series allows for rigorous quality control.

Modern Machine Shop

APRIL 4, 2023

The Ceratizit ToolScope monitoring and control system consists of a suite of specialized modules — process control, machine protection, digitization and documentation — aimed at measuring and optimizing particular aspects of machining operations.

Fabricating & Metal Work

MAY 1, 2024

The swivel movement reduces the time it takes for regripping, improving overall cycle time. Easy-Form Laser uses adaptive, in-process control over the bend angle. PRECISE PART PRODUCTION Easy-Cell is equipped with LVD’s Easy-Form® Laser for bend accuracy assured from the first part.

Modern Machine Shop

JUNE 13, 2024

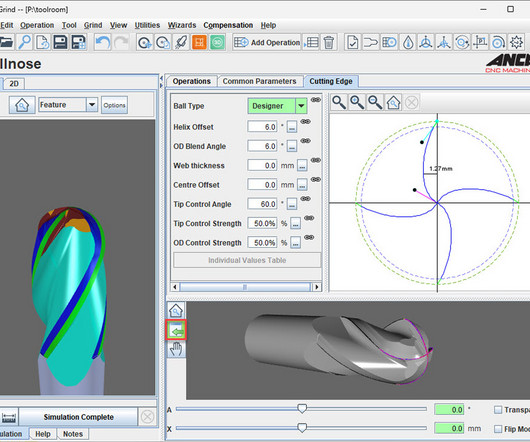

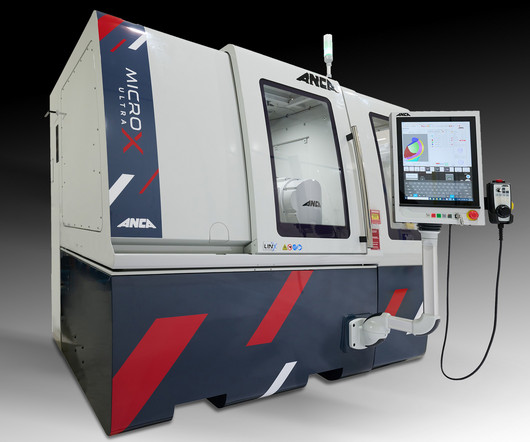

Feed rate is optimized, improving cycle time and surface finish while extending wheel life. New developments including the integration of material removal rate calculations, enabling manufacturers to automatically set parameters for constant removal rates, plus air-time reduction.

Fabricating & Metal Work

MAY 16, 2024

Building on ANCA’s heritage of producing industry-leading software, the latest release of our signature ToolRoom software, RN35, takes cycle time optimization even further, elevating productivity – it’s the future of tool production.” ToolRoom and AIMS really pave the way for highly productive, autonomous production.

Modern Machine Shop

NOVEMBER 12, 2024

Low-mix, high-volume shops can leverage data to eliminate variability in machining performance in several ways, including identifying optimal predictive maintenance schedules and fine-tuning processes to achieve consistent, repeatable cycle times. Tech-forward high-mix, low-volume job shops use data very differently.

Control Engineering

FEBRUARY 8, 2023

It could be something as simple as a pump or a fan for a process control application, with a simple drive, typically open loop. There’s no need for clock synchronous application operation, because it’s a very simple application.The cycle times, ver roughly, are tens of millisecond. It’s not infinite.

ATS

APRIL 5, 2024

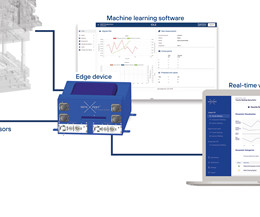

The types of signals and records a machine data collection system can gather include: Sensor data Some of the i ndustrial machine sensors used for process control can also capture machine health data. It can also cover operational information such as run time and down time. Contact us for more information.

Fabricating & Metal Work

AUGUST 10, 2022

Batch grinding on a CPX with high material removal rates and to tight tolerances is a basic function of the machine, the OD measurement system takes it further by utilizing the Statistical Process Control (SPC) feature that comes standard with the OD measurement software.

Fabricating & Metal Work

JULY 21, 2022

Batch grinding on a CPX with high material removal rates and to tight tolerances is a basic function of the machine, the OD measurement system takes it further by utilizing the Statistical Process Control (SPC) feature that comes standard with the OD measurement software.

eFlex Systems

MAY 13, 2022

Also, advanced digital work instructions can enforce process control, enable IoT devices such as torque controllers at point of use and ensure parameters are within specs. Work instructions and tasks are displayed in real-time. Get 100% time capture for each process task start & stop. As industry 4.0

i4.0 today

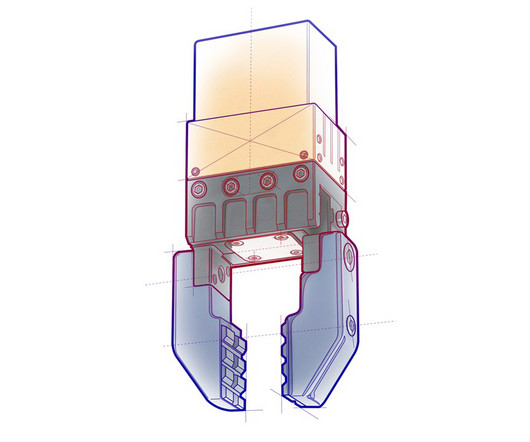

AUGUST 27, 2024

Rapidly opening and closing the grippers allows the pick, place and release mechanism to be completed quickly – reducing cycle times and improving productivity for automated systems. However, fast cycle times must be backed by repeatability. The lower the inertia of a specified gripper motor, the bigger the benefits.

Fabricating & Metal Work

AUGUST 13, 2024

FormControl X an efficient solution for operations using machine-integrated quality control of workpieces in series production. The software enables automated monitoring of machining processes in line with the principle of statistical process control (SPC).

i4.0 today

JUNE 17, 2024

It really does depend on cycle time, process demand (materials processed, quality of tooling, tool weights, number of functions utilised etc.,) Using machine data such as loads, cycle times etc., Especially when customer schedules and stock holdings are so reliant on quick, seamless component deliveries.

Modern Machine Shop

JANUARY 15, 2023

. “But he really ramped up the technology very quickly over a short period of time.” ” The shop had the first non-captive CNC in the area, and was on the leading edge of statistical process control (SPC). “It actually was a solid purchase,” she says.

Frost & Sullivan Manufacturing

JUNE 30, 2022

In-line metrology solutions : Provide real-time quality control through in-line metrology equipment and advanced software. Integrate AI and ML : Reducing product design and part tolerancing cycle time can be achieved through metrology data-fed AI engines.

Fabricating & Metal Work

AUGUST 2, 2024

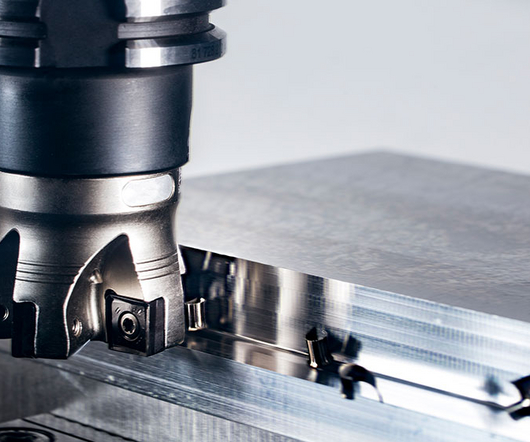

Behind the scenes, Shop A dealt with several issues to get to the finished product: long cycle times, inconsistent bore quality, reduced tool life and scrapped parts. A few examples: Selecting the correct insert and cutting parameters is essential for process control. At first glance, you’d think the two are identical.

Fabricating & Metal Work

AUGUST 2, 2024

Behind the scenes, Shop A dealt with several issues to get to the finished product: long cycle times, inconsistent bore quality, reduced tool life and scrapped parts. A few examples: Selecting the correct insert and cutting parameters is essential for process control. At first glance, you’d think the two are identical.

Fabricating & Metal Work

AUGUST 1, 2024

www.aimsmetrology.com New Technology for Automation, Tool Monitoring and Process Control Booth E-134742: Caron Engineering will showcase its latest technology for automation, tool monitoring and process control. Using adaptive control TMAC will adjust feed rates in real time to reduce cycle time up to 60% on some cuts.

MEM

MAY 25, 2023

When looking at the chemical reaction, separation and purification stages, automated process control strategies should be applied to optimise the operating conditions. On the PAT watch A highly effective solution is setting up self-regulating processes driven by Process Analytical Technology (PAT).

i4.0 today

NOVEMBER 7, 2022

Being shown for the first time at K 2022, the new Branson GLX-1 laser welder is an efficient, highly automated, connected system that maximizes efficiency and optimizes equipment effectiveness. The new GLX-1 laser welder has a small footprint, integrating seamlessly into automated joining systems. Branson GMX-20MA.

CMTC Manufacturing Tech

DECEMBER 23, 2021

These costs might include product inspection, product testing labs, auditing process controls, preventative maintenance, supplier development, and more. Measure the success of your efforts to reduce defects, rework, and cycle time in order to see the impact that quality has on your organization. Internal Failure Costs.

Fabricating & Metal Work

JULY 18, 2024

The magnetic field and thus the welding parameters can be controlled very precisely, thus providing a constant, documentable quality. With an EMPT system, up to ten busbar joints can be performed per pulse with cycle times of five seconds or more. This makes this welding process commercially cost-efficient.

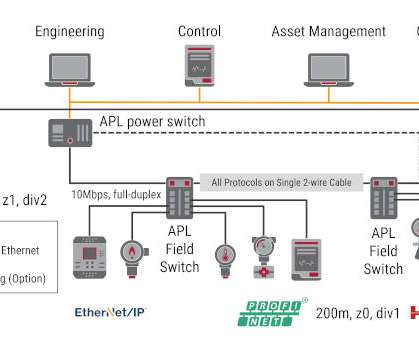

Control Engineering

SEPTEMBER 8, 2022

The HART communication protocol is a digital information exchange between a smart process control field device. Ethernet-APL combines existing digital communication technologies in the process manufacturing industry. Ethernet-APL combines existing digital communication technologies in the process manufacturing industry.

iBASEt

APRIL 26, 2023

This type of closed-loop quality system is essential to achieving higher levels of quality while improving cycle time and assuring regulatory compliance with AS9100 standards. Nonconformance and corrective action procedures are automatically triggered and routed for disposition.

Frost & Sullivan Manufacturing

AUGUST 28, 2024

Grand-CHO technology enables high-density and large-scale cell storage, while seamlessly integrating a 3,000L N-1 perfusion process and a 30,000L intensified Fed-batch production process. PCM’s success is driven by the interconnected equipment enabled by PanFlex®-Engineering.

Fabricating & Metal Work

JUNE 14, 2024

Added Edmund Boland, ANCA’s general manager, “Building on ANCA’s heritage of producing industry-leading software, the latest release of our signature ToolRoom software, RN35, takes cycle time optimization even further, elevating productivity – it’s the future of tool production.”

Mold Making Technology

DECEMBER 4, 2022

End-to-End Conformal Cooling Design, Production for Faster Cycle Times, Boosted Part Quality. Cooling is a critical process for plastic injection molds, affecting both cycle time and final part quality, Cimatron notes, but is especially challenging for complex parts when using traditional drilling and milling methods.

Fabricating & Metal Work

JUNE 17, 2024

The swivel movement reduces the time it takes for regripping, improving overall cycle time. Easy-Form Laser uses adaptive, in-process control over the bend angle. Easy-Cell is equipped with LVD’s Easy-Form® Laser for bend accuracy assured from the first part.

Control Engineering

MARCH 14, 2023

He’s also supported customers navigating the complex transition from manual processing to automation for products ranging from gelatin and pudding to fire trucks and grain trailers. He specializes in process control system design, implementation, testing, and validation.

Dinesh Mishra

JANUARY 30, 2023

This long-term partnership has allowed Marposs to absorb the knowledge of the process requests for improvement, leading to the development of a complete range of solutions and a product portfolio that is nowadays an absolute worldwide reference. For more information, please get in touch with us at info.metrology.in@zeiss.com

Fabricating & Metal Work

MARCH 20, 2025

The convergence of robotics and automation with intuitive no-code programming enables machinists to reduce cycle times and increase productivity, even when machining the hardest to cut materials. By enabling faster cycle times and enhancing tool performance, manufacturers can drive up profits.

Expert insights. Personalized for you.

We have resent the email to

Are you sure you want to cancel your subscriptions?

Let's personalize your content