What is Driving Mold Lifecycle Management Digitalization?

Mold Making Technology

MARCH 29, 2023

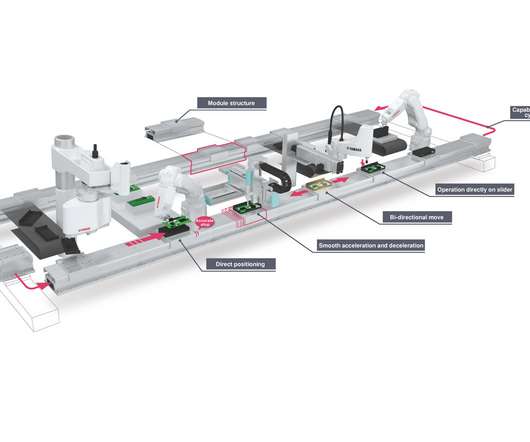

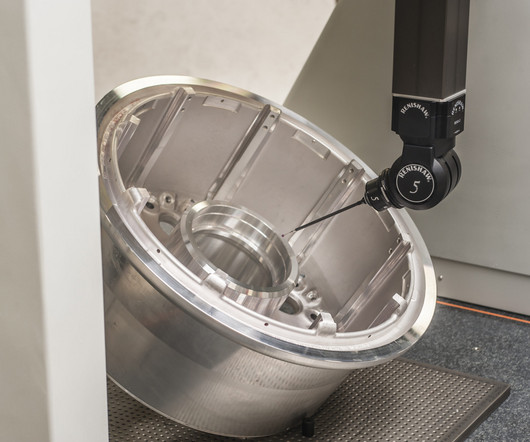

IIoT Technology and Tooling Digitization The answer was adopting Industry 4.0 and Industrial Internet of Things (IIoT) concepts. VanCoillie explains that Industry 4.0. “Industry. IIoT is manifested in equipment, whereas Industry 4.0 Applying Industry 4.0 ” Industry 4.0

Let's personalize your content