Supply chain management unlocks manufacturing financial power

Manufacturer's Monthly

OCTOBER 30, 2024

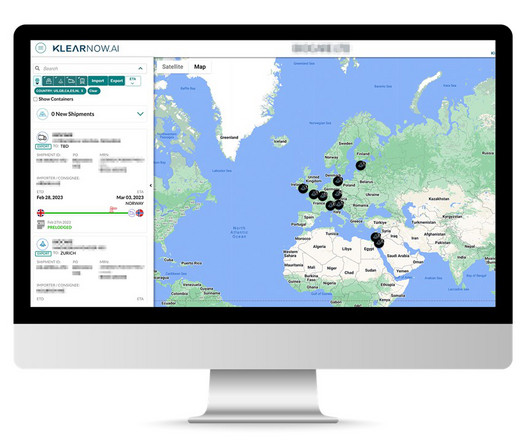

Image: kerkezz/stock.adobe.com ECI Solutions’ M1 ERP transforms supply chain management by fostering collaboration, streamlining operations, improving efficiency, and unlocking cost savings. Imagine a world with partners, not headaches The supply chain arena is filled with the victims of obsolete strategies.

Let's personalize your content