Digitizing an entire factory to Industry 4.0

Quantis

NOVEMBER 22, 2022

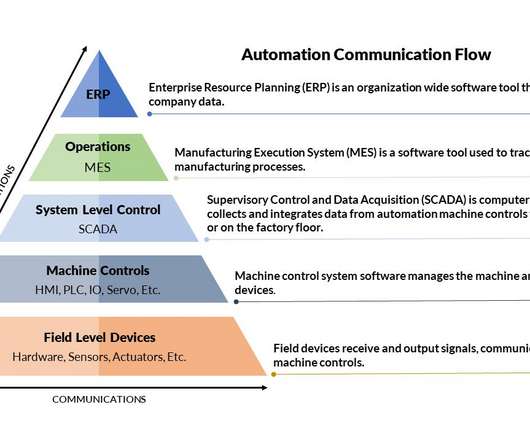

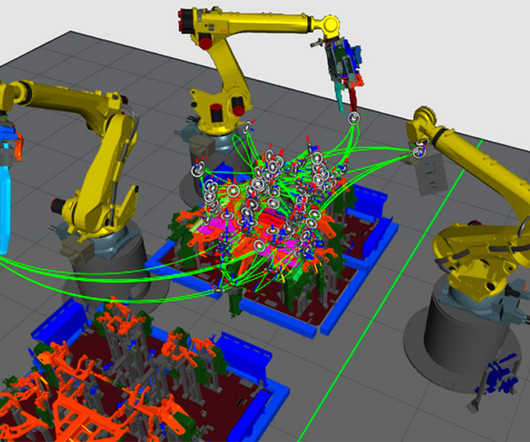

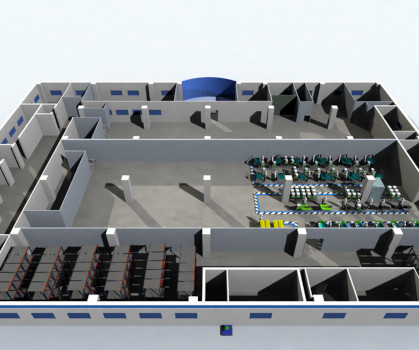

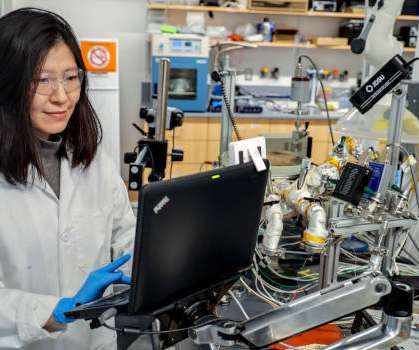

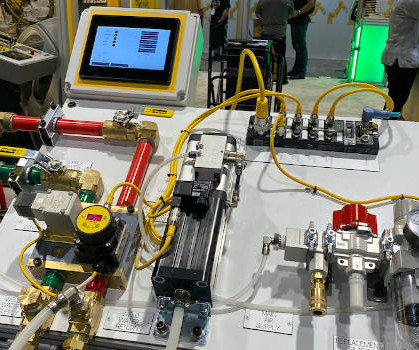

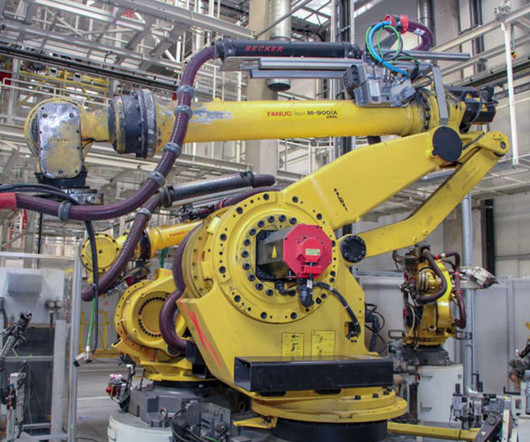

After all, a factory exists as a heterogeneous landscape of different technologies, machines, manufacturers (OEM), robots and components. The added value of converting individual lines to Industry 4.0 The conversion of the entire factory to Industry 4.0 Digitizing an entire factory sounds like an unsolvable task.

Let's personalize your content