Robotics Algorithms Identify and Eliminate Production Bottlenecks

Automation World

JANUARY 22, 2024

System Integrator Valiant TMS uses Realtime Robotics tech to reduce cycle time by 17%.

Automation World

JANUARY 22, 2024

System Integrator Valiant TMS uses Realtime Robotics tech to reduce cycle time by 17%.

Robotics Business Review

DECEMBER 1, 2024

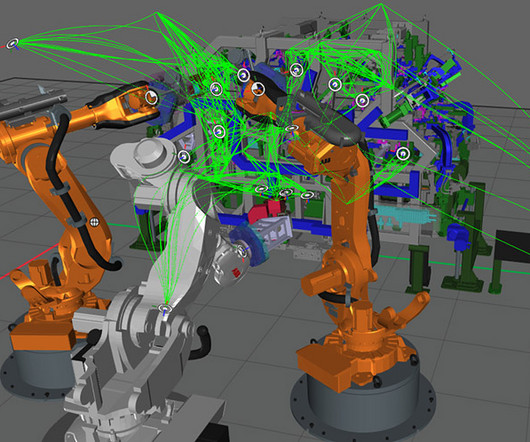

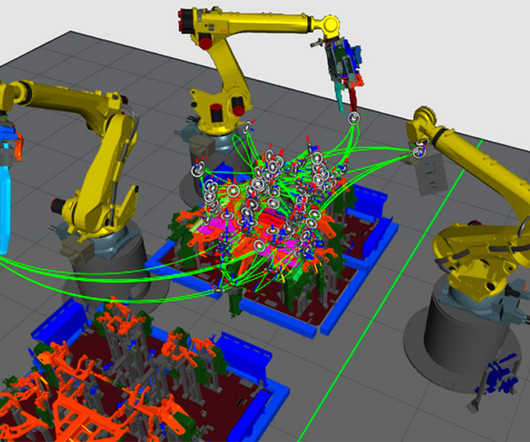

Optimization evaluates multiple paths, sequences, poses, end-of-arm tool rotations, and interlocks for robots within a workcell. Source: Realtime Robotics. Realtime Robotics, a leader in collision-free autonomous motion planning for industrial robots, last week named industry veteran Ville Lehtonen as its vice president of product.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Robotics Business Review

JANUARY 8, 2024

Valiant TMS is integrating robot motion optimization as a service. Source: Realtime Robotics Realtime Robotics today announced that Valiant TMS will integrate its Optimization-as-a-Service offering with customers’ manufacturing operations. “They can reap the benefits without wasting hours of their team’s time.”

Robotics Business Review

JUNE 27, 2024

The Optimization system generates motion plans and avoids collisions in multi-robot workcells. Source: Realtime Robotics While conventional manufacturing involves robots working along a well-defined production line, software can enable multiple robots to work together more closely without collision for more complex and flexible processes.

Control.com

DECEMBER 14, 2023

Realtime Robotics has partnered with HLS Engineering Group to enhance automation cell optimization, aiming to eliminate production bottlenecks and reduce cycle times within a matter of weeks.

Fabricating & Metal Work

DECEMBER 19, 2023

Realtime Robotics , the leader in collision-free autonomous motion planning for industrial robots, recently announced the launch of its new Optimization-as-a-Service solution. The company was looking to quickly and efficiently improve the cycle time in a 2-robot cell that was welding car doors for the ID.

Gary Mintchell

JANUARY 10, 2023

Machine vision has been usable since the 1980s to detect flaws, presence, and other quality issues, as well as to guide robots. You have been trying to point out bottlenecks to production on your machine. The video analytics point out the bottleneck. Low process efficiency—cycle time variability, too many interruptions.

Let's personalize your content