Inventory management key to maintaining a competitive edge

Manufacturer's Monthly

MARCH 11, 2025

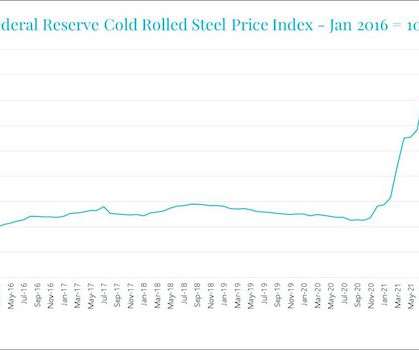

Image: /stock.adobe.com For Australia’s discrete manufacturers, inventory management is pivotal in ensuring the smooth operation of production processes, maintaining product quality, and achieving sustainable growth. Efficient inventory management helps manufacturers save resources, cut costs, and avoid disruptions.

Let's personalize your content