Improving efficiency through algorithmic production scheduling

Control Engineering

OCTOBER 8, 2023

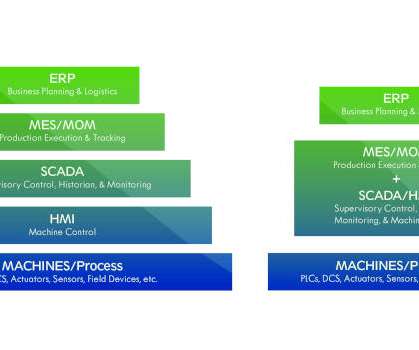

TrakSYS APS downloads the production orders, routing options and product attributes from the existing enterprise resource planning (ERP) and supervisory control and data acquisition (SCADA) systems then runs these through an algorithm in order to develop an optimal production schedule sequence.

Let's personalize your content