What’s Holding Back Aluminum Recycling?

21st Century Tech

DECEMBER 28, 2024

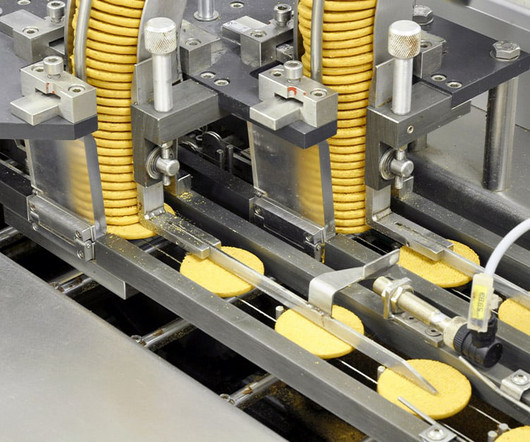

Please welcome back Ellie Gabel to the 21st Century Tech Blog. mostly consisting of food and beverage containers. Aluminum 3004 is used in pipes, beverage cans and building materials, while 5052 alloys are widely used for boats, fuel tanks, cars and road signs. She is a big fan of Richard Dawkins. Landfills absorbed 2.7

Let's personalize your content