Flexpipe announces the launch of its Lean Maker Academy to support lean manufacturing

Canadian Manufacturing

AUGUST 16, 2023

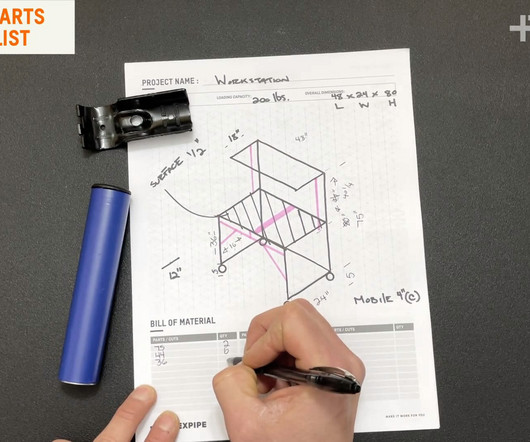

Flexpipe announces the launch of its Lean Maker Academy to support lean manufacturing QUEBEC CITY — On Aug. Flexpipe announces the launch of its Lean Maker Academy to support lean manufacturing QUEBEC CITY — On Aug. Train as many people as you want on a schedule that meets their needs and yours.”

Let's personalize your content