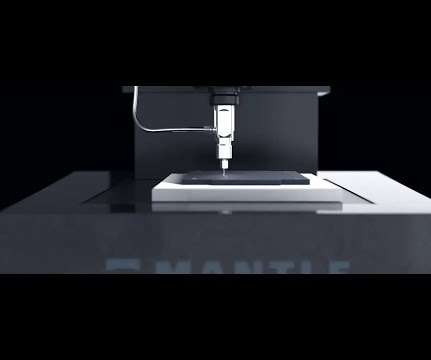

Automatic gripper changes can add flexibility in manufacturing

Robotics Business Review

FEBRUARY 16, 2025

Source: Tezmaksan Robot Technologies Production manufacturing demands are increasingly diverse, so adaptability and efficiency are essential, according to Hakan Aydogdu, CEO of Tezmaksan Robot Technologies. This flexibility lets manufacturers meet diverse customer requirements without compromising throughput.

Let's personalize your content