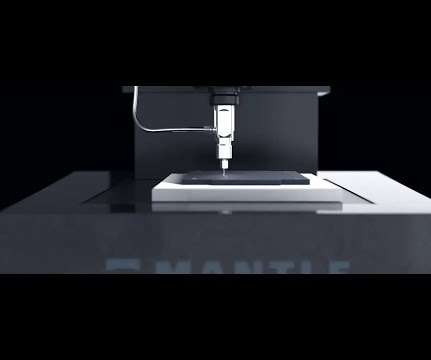

Pioneering Precision and Sustainability

Dinesh Mishra

JANUARY 22, 2025

3) With digitalization reshaping manufacturing, what new skills are essential for todays workforce, and how is the industry addressing the skills gap? In the era of digital manufacturing, coding, CAD/CAM, and data analytics have become essential skills for todays workforce.

Let's personalize your content