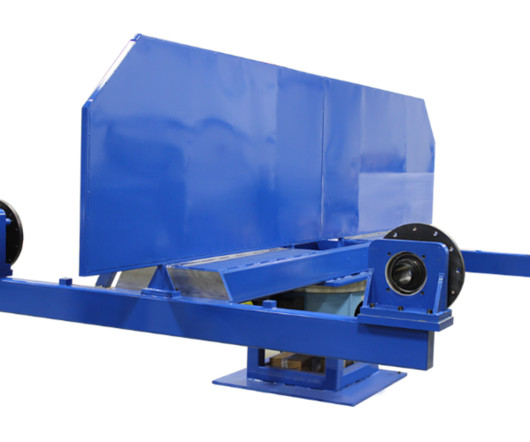

Enhancing Welding Automation with Single and Multi-Axis Weld Positioners

Design World

JANUARY 1, 2025

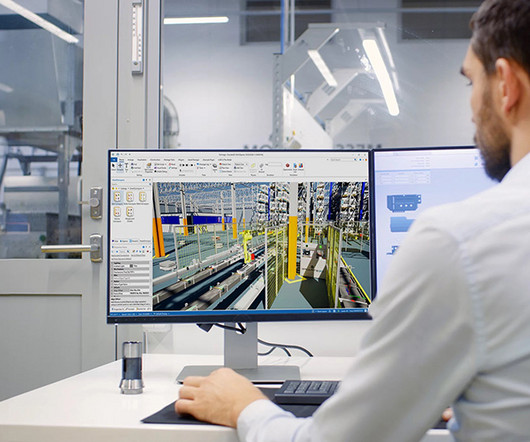

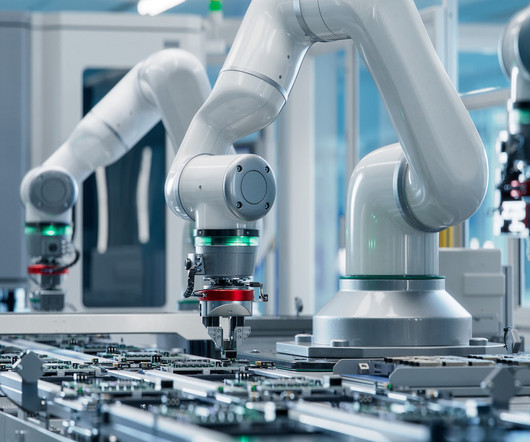

Incorporating single axis trunnions and multi-axis weld positioners into manufacturing operations significantly expands the possibilities for welding automation. These advanced systems enable manufacturers to maximize throughput, improve weld quality, and save valuable floor space.

Let's personalize your content