The Automated Factory Ushers in a New Era of Manufacturing

Automation World

DECEMBER 25, 2024

Automation is revolutionizing the way products are manufactured from traditional assembly lines to highly interconnected, data-driven factories.

This site uses cookies to improve your experience. To help us insure we adhere to various privacy regulations, please select your country/region of residence. If you do not select a country, we will assume you are from the United States. Select your Cookie Settings or view our Privacy Policy and Terms of Use.

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

Used for the proper function of the website

Used for monitoring website traffic and interactions

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

Automation World

DECEMBER 25, 2024

Automation is revolutionizing the way products are manufactured from traditional assembly lines to highly interconnected, data-driven factories.

Robotics Automation News

JANUARY 7, 2024

Comau has designed and deployed a high-volume, automated assembly line for HYCET, a wholly-owned subsidiary of Great Wall Motor and a leading manufacturer of DHT (Dedicated Hybrid Transmission) technology. The L.E.M.O.N.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Robotics Business Review

DECEMBER 26, 2024

Massimo Motor’s new production facility with automated guided robots in Garland, Texas. Source: Massimo Group Massimo Motor Sports LLC, a manufacturer and distributor of powersports vehicles and pontoon boats, has added robotics to its new assembly line to streamline production and enhance quality control. 34,931 sq.

Manufacturer's Monthly

FEBRUARY 15, 2024

When the Estonian company HOOB was asked to build a new assembly line for a global company, they looked to LINAK to meet the ergonomic goals of the project. This encouraged them to take the plunge and start HOOB, a company dedicated to the design and manufacture of assembly lines.

Automation World

AUGUST 5, 2024

From basic bin picking and placing to welding, soldering and assembly line operations, manufactures are finding collaborative robots suitable for more applications.

Automation World

DECEMBER 25, 2024

Automation is revolutionizing the way products are manufactured from traditional assembly lines to highly interconnected, data-driven factories.

Automation Mag

MARCH 17, 2025

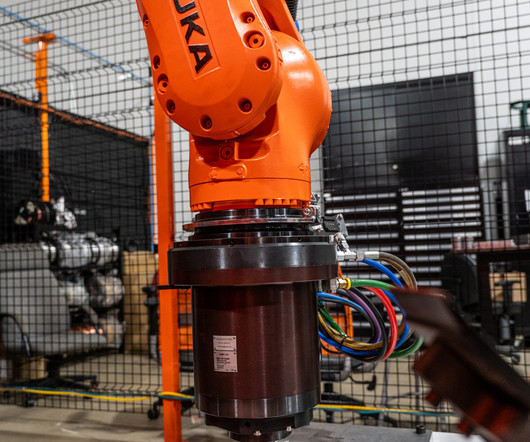

KUKA Robotics welcomed more than 200 people for Manufacturing Automation Tech Day at the companys North American headquarters in Shelby Township, Michigan on Wednesday, February 26, 2025. A direct response to on-going labor shortages, AMRs allow manufacturers to automate repeated intralogistics functions.

Manufacturing Tomorrow

SEPTEMBER 19, 2024

Let's dive into the world of manufacturing assembly line automation and discover how it's shaping the future of production.

DO Supply

DECEMBER 30, 2024

Mitsubishi servo drives are well known for their great performance, accuracy, and dependability, which can improve industrial automation. Because of all these capabilities, Mitsubishi servo drives are crucial to optimizing contemporary industrial automation processes. For instance, the MELSERVO-JN line of low-power drives (0.05

Gary Mintchell

SEPTEMBER 12, 2023

Rockwell Automation has been “the world’s largest company dedicated to industrial automation”, and then “the world’s largest company dedicated to industrial automation and software.” Now it is “the world’s largest company dedicated to industrial automation and digital transformation.” Software was sexy. Just watch.

Gary Mintchell

FEBRUARY 7, 2025

The Fuji America-Cybord solution provides a way to inspect 100% of the components on an assembly line to mitigate against these disruptions. Cybords visual AI-powered solution provides real-time inspection of 100% of electronic components during PCBA assembly with 99.9%

Robotics Automation News

MAY 19, 2023

Humatics is planning to showcase what it says is “an industry first” – an in-motion engine assembly application with multiple robotic arms working concurrently in the same pitch. The company will show off its new microlocation technology at this year’s Automate Show in Detroit, Michigan.

Fabricating & Metal Work

MARCH 20, 2025

At Manufacturing Automation Tech Day, KUKA showcased its newest AMRs the KMP 600P, KMP 1500P and KMP 3000P. KUKA Robotics opened its doors to more than 200 people for Manufacturing Automation Tech Day at the companys North American headquarters in Shelby Township, Michigan on Wednesday, February 26, 2025.

Control.com

APRIL 1, 2024

The new BGL fork sensor series by Balluff eases the entry into automated object detection. The cost-effective sensors are easy to install and configure for assembly line and work cell automation.

Automation Mag

SEPTEMBER 19, 2024

One of the seven newly created schools is the School of Manufacturing and Automation , offering programs tailored to meet the demands of the manufacturing and automation sectors. Today, the best quality products are made by automated machines, using processes that are designed by people. However, that is no longer the case.

Robotics Business Review

NOVEMBER 11, 2024

ABB (Switzerland), a global leader in electrification and automation, is based in Zurich and has more than 105,000 employees worldwide. With over 140 years of experience, the company integrates software and engineering to optimize manufacturing, energy, and automation processes.

Manufacturer's Monthly

MARCH 17, 2025

Compressed air specialist ELGis facilities run on precision engineering, innovation, and sustainability with automated assembly lines, advanced quality control, and eco-friendly practices that ensure every part and product meets quality and efficiency standards.

Frost & Sullivan Manufacturing

JULY 23, 2024

Frost & Sullivan’s Manufacturing webinar series delved into the topic ‘ Transitioning from Assembly Lines to Smart Factories for the Future.’ appeared first on Frost & Sullivan.

Frost & Sullivan Manufacturing

JULY 23, 2024

Frost & Sullivan’s Manufacturing webinar series delved into the topic ‘ Transitioning from Assembly Lines to Smart Factories for the Future.’ appeared first on Frost & Sullivan.

Frost & Sullivan Manufacturing

JULY 23, 2024

Frost & Sullivan’s Manufacturing webinar series delved into the topic ‘ Transitioning from Assembly Lines to Smart Factories for the Future.’ appeared first on Frost & Sullivan.

Canadian Manufacturing

FEBRUARY 27, 2023

Martel foods automates its sandwich lidding line. As a long-time customer of Grote Company, they turned to the food processing equipment manufacturer to help automate this process. It’s built into their existing sandwich assembly line, which features Grote’s Bread Denester and Ultrasonic Sandwich Cutter.

Control Engineering

AUGUST 14, 2022

Implementing 5G and mobile edge computing is helping companies reap the benefits of automated technological solutions through digital transformation. AI and ML usage in assembly lines increases efficiency, reduces costs and improves accuracy. Developing smart assembly lines. Learning Objectives. Courtesy: Verizon.

Gary Mintchell

OCTOBER 25, 2022

ABB is the only company with a comprehensive and integrated offering of robots, AMRs and machine automation solutions. ABB has worked with strategic partner Expert Technology Group in the UK to deliver a complete assembly line based on AMRs for a technological. The first models to be released, Flexley Tug and Flexley Mover.

Automation Mag

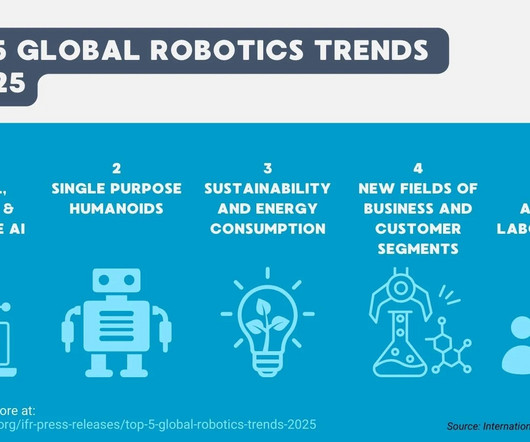

JANUARY 22, 2025

2 Humanoids IFR explains that robots in the shape of human bodies will become general-purpose tools that can load a dishwasher on their own and work on an assembly line elsewhere. These automated systems ensure consistent quality which is essential for products designed to have long lifespans and minimal maintenance.

Robotics Business Review

DECEMBER 17, 2024

Prototype of the Eyeonic Trace Laser Line Scanner, designed to provide submillimeter depth precision for next-generation warehouse automation, robotics, farming, construction and manufacturing applications. The new Eyeonic Trace Laser Line Scanner provides better depth precision than the human eye,” he added.

Manufacturer's Monthly

AUGUST 1, 2022

It’s imperative that businesses take a careful look at the signs of stress and strain injuries among workers to decide whether it’s time to pivot to automation.”. Collaborative automation is changing the landscape as we know it and is empowering employees,” he said. Is it time to automate? Empowering employees.

Manufacturer's Monthly

AUGUST 20, 2023

A key aspect of this transformation is the increasing automation of manual processes, with motion control playing a pivotal role in driving this shift, says Beckhoff experts. Motion control is a specialised area of automation that precisely controls the movement of individual components in a machine.

Robotics Business Review

JUNE 30, 2022

For manufacturers and others, tow-lines for assembly line conveyance deliver solid ROI, but AGVs and AMRs can provide equal efficiencies and value, with the added benefits of greater scalability and flexibility. The post AGVs & AMRs as Alternatives to Tow Line Conveyance appeared first on Robotics Business Review.

Robotics Business Review

FEBRUARY 4, 2025

Source: PIA Automation Medical devices require precise and consistent manufacturing. PIA Automation Holding GmbH, a provider of modular assembly lines and process automation, is highlighting the development of its V-RAC module, which can be adjusted to handle various drug-delivery devices.

Robotics Automation News

FEBRUARY 6, 2023

BMW Group Plant Leipzig’s first cell coating line has gone into series operation as e-component production at the site continues to gain momentum. By 2024 the two existing module assembly lines will be complemented by a third, as well as four more cell coating lines and two more high-voltage battery assembly lines.

Gary Mintchell

NOVEMBER 30, 2023

All of us who have ever developed automation systems know that when the automation gets in the way of the work, then the worker will turn it off. Funding will be used to meet the increased market demand for its proprietary generative AI technology, Retrocausal’s Kaizen Copilot software for Manufacturing Assembly Optimization.

Robotics Automation News

MARCH 27, 2024

From the assembly lines of automotive giants to the delicate operations in electronics manufacturing, AI […] In the vast and complex world of manufacturing, the advent of Artificial Intelligence (AI) and robotics marks a significant turning point.

Manufacturing Tomorrow

DECEMBER 13, 2023

Comau has developed and deployed a fully automated, high-volume manufacturing line to produce the L.E.M.O.N. hybrid transmission system

Modern Machine Shop

SEPTEMBER 3, 2023

With 10% of its job openings going unfilled company-wide, Thyssenkrupp Bilstein has relied heavily on integrating automation into its workflow. That might sound strange, but at Thyssenkrupp Bilstein ’s Hamilton, Ohio, facility, the collaborative robots (cobots) that help with automation projects and part inspection are named after U.S.

Robotics Automation News

JULY 29, 2022

To make this switch possible, these companies relied on people working on an assembly line. At the beginning of the Covid-19 pandemic, car manufacturing companies such as Ford quickly shifted their production focus from automobiles to masks and ventilators.

Automation Mag

MAY 6, 2024

Comau started offering industrial automation solutions for the automotive sector more than 50 years ago for many of the world’s biggest car manufacturers. As automation technology has changed over the years, so has its reach. For these reasons, Comau’s advanced solutions are also increasingly accessible and intuitive.

i4.0 today

DECEMBER 15, 2022

Here, Beckhoff UK explains how automation can optimise workflow in factories as complex as a Santa’s and relieve pressure on the elves. When controlled by an industrial PC with TwinCAT software, the XTS linear transport system can move the presents through the assembly line, with its magnetically driven movers. Gartner, Inc.

MEM

DECEMBER 15, 2022

Here, Beckhoff UK explains how automation can optimise workflow in factories as complex as a Santa’s and relieve pressure on the elves. When controlled by an industrial PC with TwinCAT software, the XTS linear transport system can move the presents through the assembly line, with its magnetically driven movers. Gartner, Inc.

i4.0 today

FEBRUARY 12, 2025

The flexible and robust amplifier is available in two domain-specific firmware choices, tailored to meet specific industrial and weighing application needs: the first is digiBOX Industrial, which has been engineered to handle the requirements of modern industrial production such as press-load monitoring, joining-processes and assembly lines.

DO Supply

FEBRUARY 6, 2023

Automation is not a new concept and has been used for many years to help businesses improve efficiency, reduce human error, and increase production. Examples of early automation include the printing press, sewing machine, and assembly line for cars.

Automation Mag

OCTOBER 3, 2023

The company will use the funds to add a new assembly line with state-of-the-art technology. The new technology will increase production and add more automation, lowering costs and giving the company a competitive edge. PWO Canada, the first international subsidiary of German auto parts manufacturer PWO Group, is investing $9.6

Motion Control Tips

APRIL 12, 2023

Fast-food restaurants across the globe are pondering ways to automate certain tasks or entire assembly lines to provide continuous service […] The post The latest developments in fast food automation appeared first on Motion Control Tips.

Robotics Business Review

JULY 12, 2024

The patented technology enables a safe and efficient solution for our customers who want to replace manual forklifts with automated material handling for production lines. The post FlexQube granted patents for Navigator AMR appeared first on The Robot Report.

Metrology

SEPTEMBER 17, 2023

Transporting parts and materials to assembly lines and between manufacturing cells is one of the industry’s most complex and inefficient tasks, often resulting in production bottlenecks.

Expert insights. Personalized for you.

We have resent the email to

Are you sure you want to cancel your subscriptions?

Let's personalize your content