Partner with Us: Upskill Australia’s Manufacturing Leaders

Manufacturer's Monthly

MAY 1, 2024

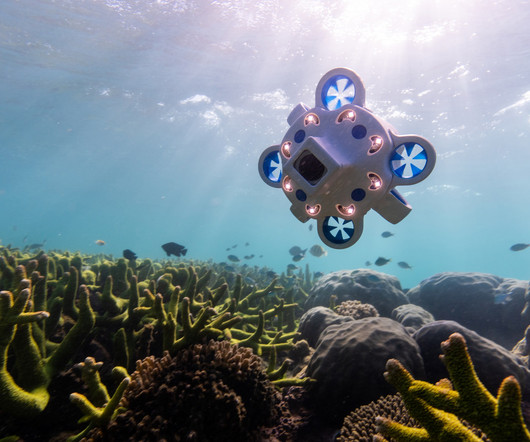

Our extensive readership spans the full spectrum of the manufacturing sector, from automotive to aerospace and every niche in between, including chemical, energy equipment, and construction materials manufacturers. It’s about becoming a trusted partner in the growth and development of Australia’s manufacturing industry.

Let's personalize your content