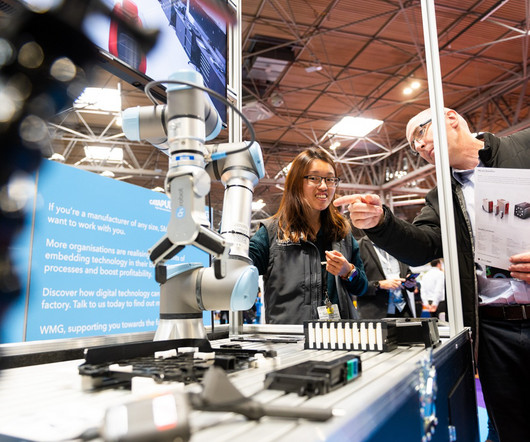

Additive manufacturing roundtable at Plastics Live 2024, a free event

Design World

MARCH 5, 2024

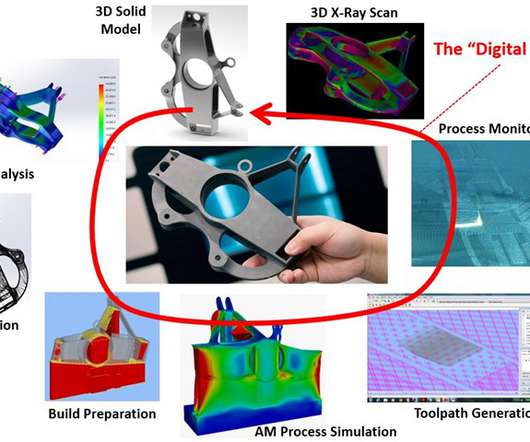

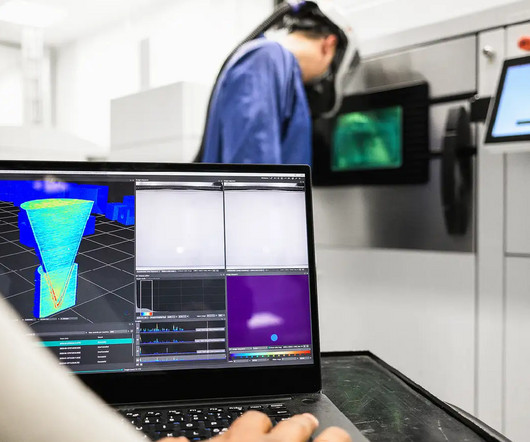

additive manufacturing (AM) scene. The team sees plastic manufacturing as incorporating technologies and issues that in many instances are seen as separate concerns for mainstream plastic production, such as AM, smart manufacturing, Industry 4.0, and environmental and sustainability issues.

Let's personalize your content