How additive manufacturing capabilities can boost Australian aerospace and defence industry growth

Manufacturer's Monthly

MARCH 13, 2023

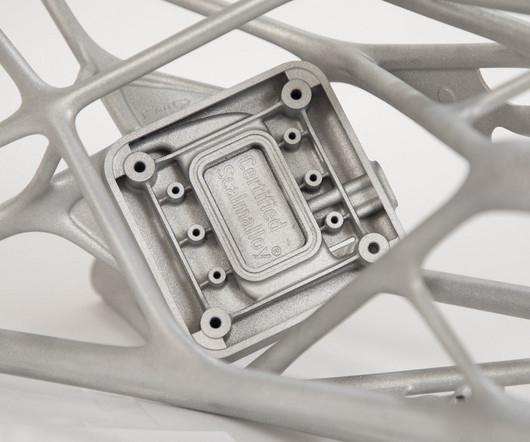

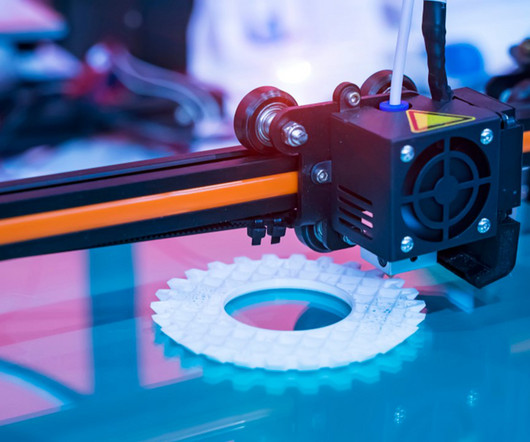

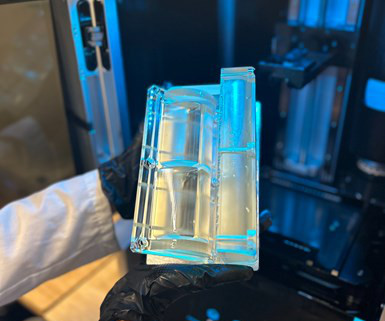

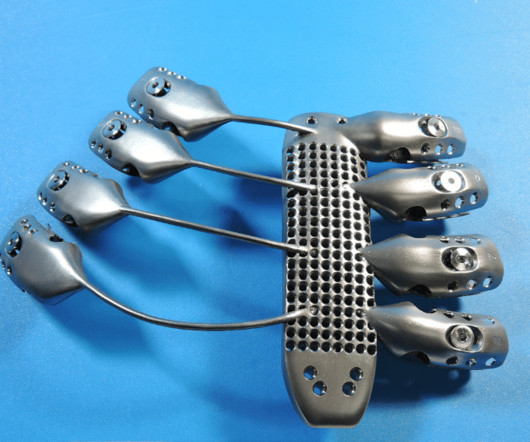

Bringing 3D printing, also known as additive manufacturing, in-house, rather than outsourcing it to offshore providers, creates additional capacity for critical research and development, keeping • organisations at the forefront of what is possible. The aerospace and defence industries face several unique and complex challenges.

Let's personalize your content