APWORKS and Equispheres announce additive manufacturing collaboration

Canadian Manufacturing

APRIL 8, 2025

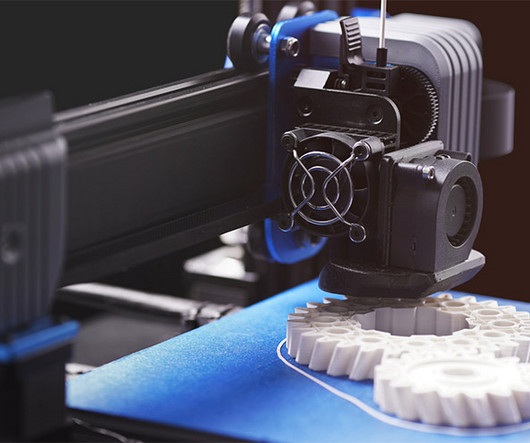

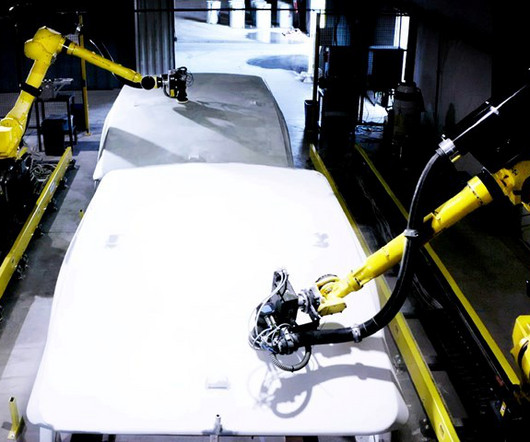

OTTAWA APWORKS and Equispheres announce a collaboration on the development of North American production capacity for Scalmalloy, a proprietary aluminum alloy designed specifically for Additive Manufacturing (AM). Were excited to be in discussions with APWORKS about producing this high-strength alloy for aluminum parts.

Let's personalize your content