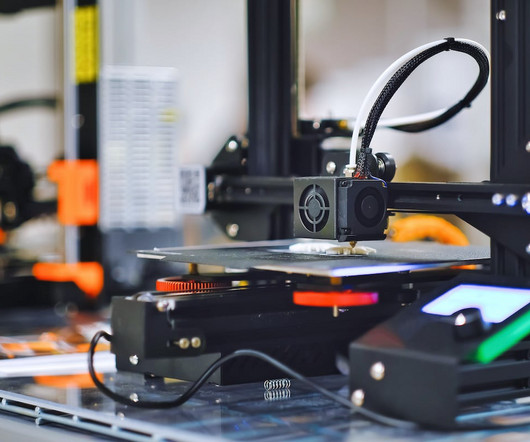

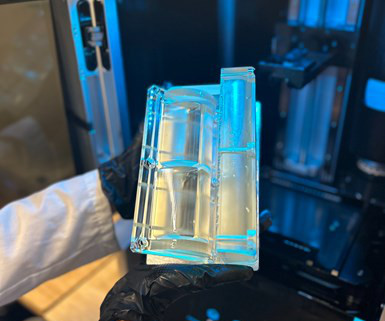

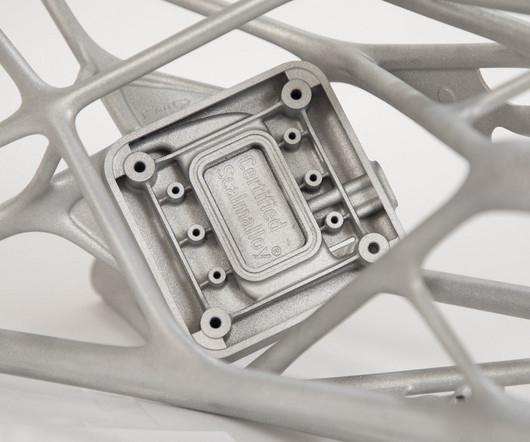

3D Printing — so what?

AU Manufacturing

OCTOBER 20, 2022

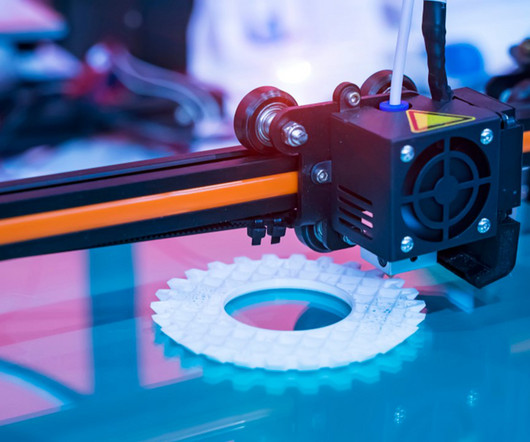

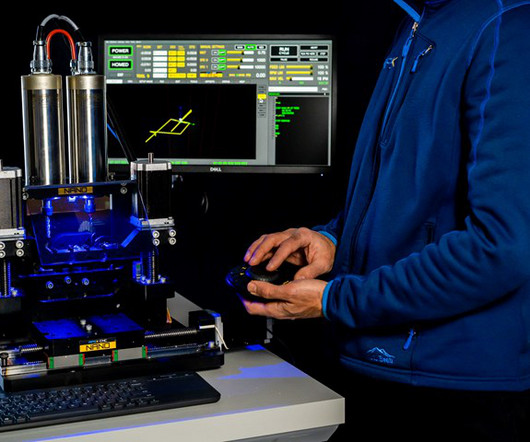

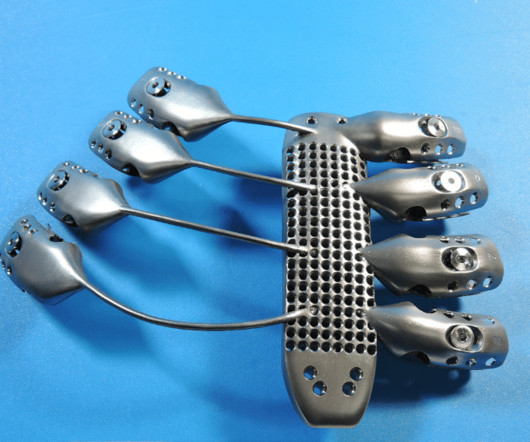

As a company, 3DPRINTUK is embedded in the additive manufacturing (AM) / 3D printing world. As such, we can advise you on issues relating to technology and material choice, orientation of parts in a build area to maximise return, design for AM, etc… etc… We live and breathe 3D printing every day. Now let’s take a leap.

Let's personalize your content