3D Printing for Aerospace – Quality Requirements

Additive Manufacturing

NOVEMBER 11, 2022

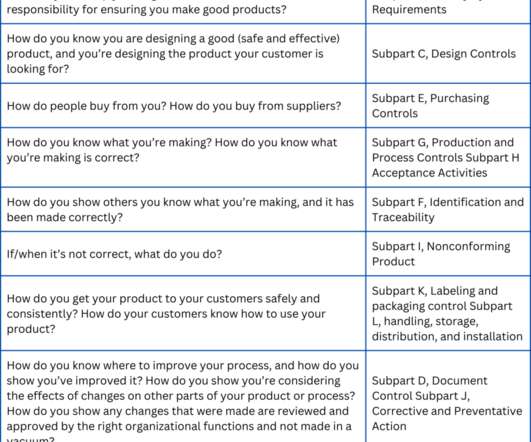

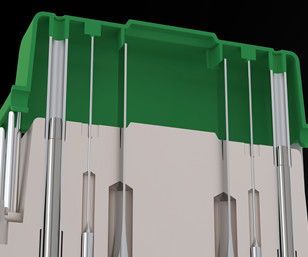

Honeywell, Boeing, and Lockheed Martin are all using 3D printing for critical parts. Honeywell and Boeing are finding vast time and cost savings in printing parts for aging fleets. All 3D printing systems used in the aerospace field need to be based on a strong quality management system.

Let's personalize your content