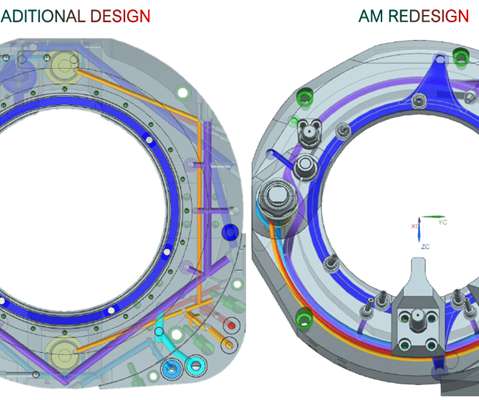

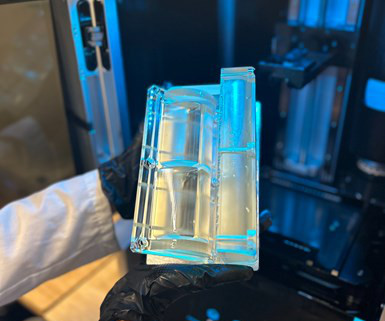

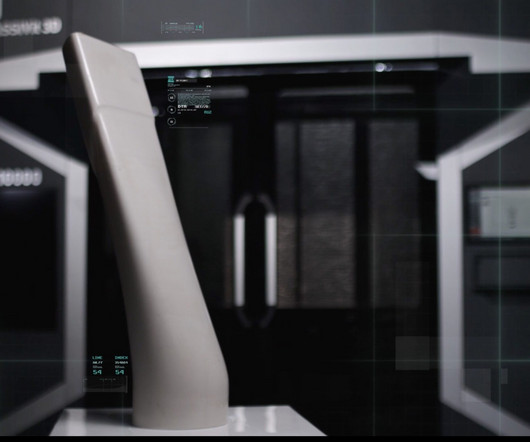

3d printing a drone’s tail rotor gear box housing

Design World

SEPTEMBER 29, 2022

FLYING-CAM, a leader in design and manufacturing of unmanned helicopters and pioneer of professional drone filming services, celebrated its 30th anniversary with the World premiere of Discovery, its newest unmanned aircraft system. The post 3d printing a drone’s tail rotor gear box housing appeared first on Design World.

Let's personalize your content