How 3D printing is reshaping the future of supply chains

Manufacturer's Monthly

NOVEMBER 21, 2022

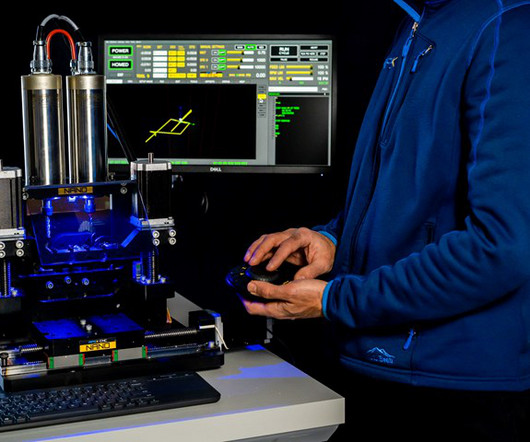

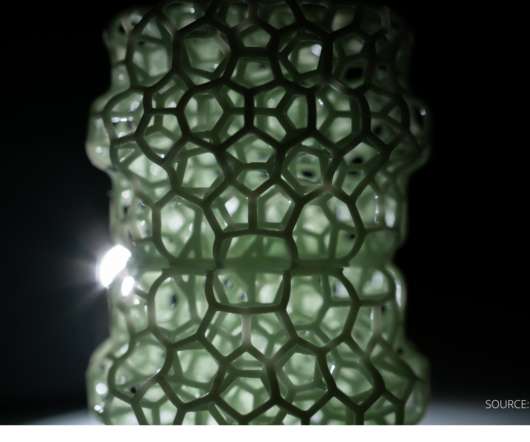

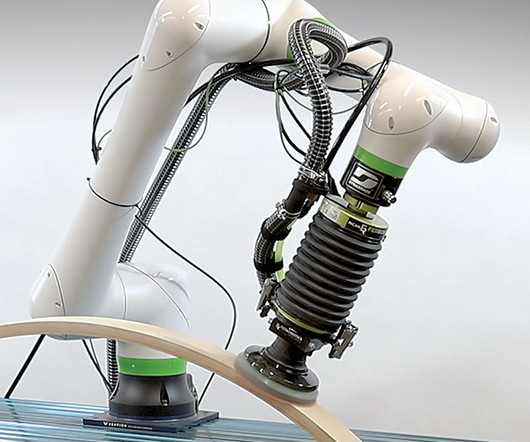

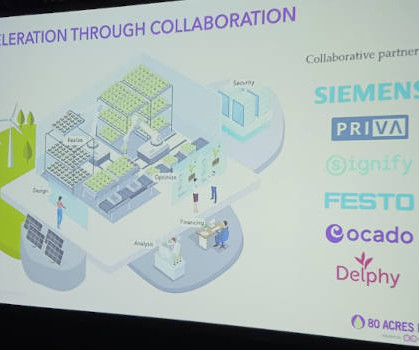

Recent changes to the supply chain emerged shortly after the global pandemic was announced, particularly during COVID-19 lockdowns, due to abrupt shifts in demand that created bottlenecks at ports worldwide. Tackling supply chain uncertainty with 3D printing. reduced costs. reduced transportation.

Let's personalize your content