Top Manufacturing Technologies Driving the Future of Automotive & Aerospace Industries

Frost & Sullivan Manufacturing

FEBRUARY 12, 2025

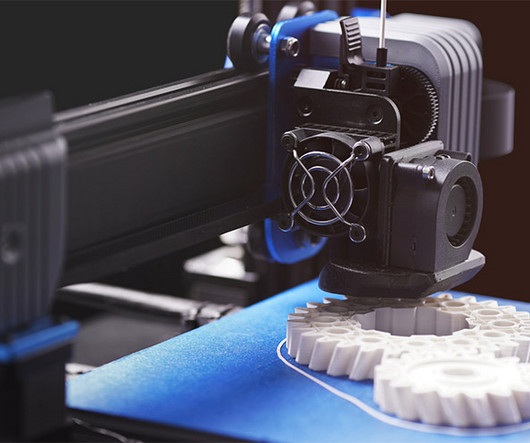

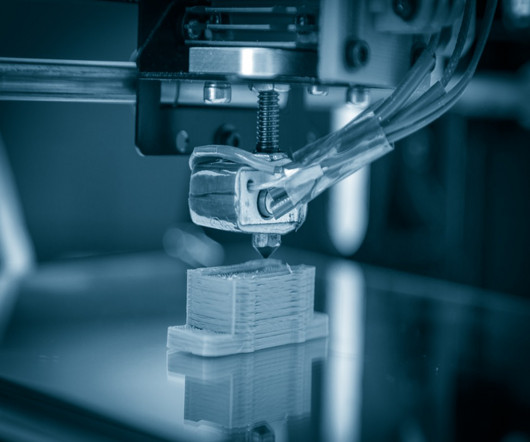

The automotive and aerospace manufacturing industries are undergoing a profound transformation fueled by the rapid adoption of electric vehicles (EVs), sustainable aviation fuels (SAFs), and smart manufacturing technologies. Innovation Acceleration : Technologies like 3D printing enable rapid prototyping and design flexibility.

Let's personalize your content