Proximity: The supply chain revolution every distributor needs to lead

Fastener News Desk

SEPTEMBER 8, 2024

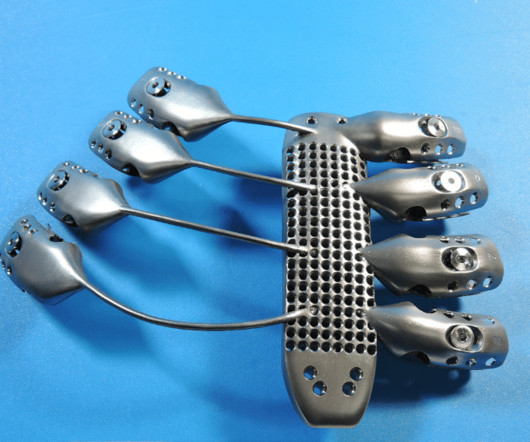

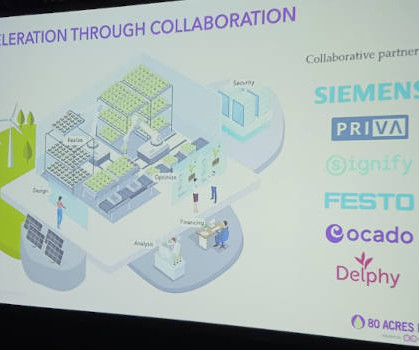

Mark Dancer on Flourishing Business Distributors have a unique opportunity to embrace a revolutionary vibe, navigate breakthroughs, and transform the supply chain from the ground up—if they are willing to become bold changemakers. Proximity is 3D printing, vertical farms, solar panels, streaming media, remote healthcare, and more.

Let's personalize your content