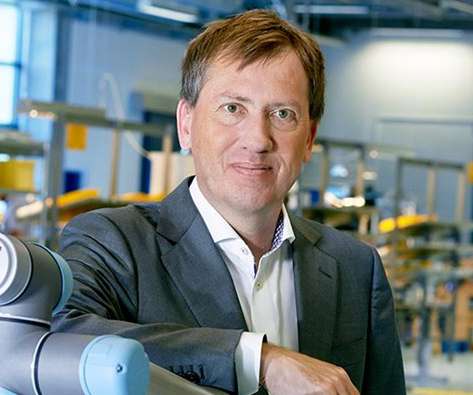

Put the soul back in work and products

Universal Robots

JANUARY 29, 2016

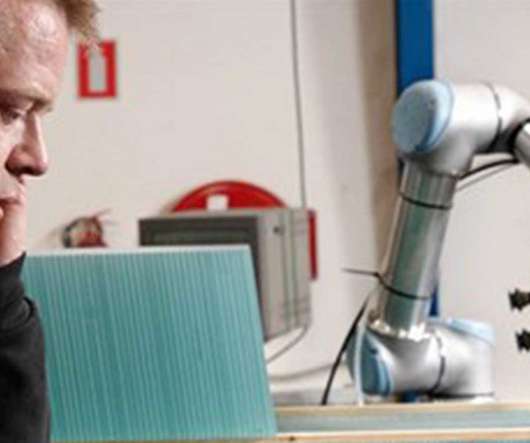

In the industry today, we maintain a barrier between human and machine work. But the industrial value creation of tomorrow is to be found in the fusion, between humans and robots. Will robots make us all unemployed? No, because we do not have, nor will we ever have, machines and technology that can take over all jobs.

Let's personalize your content