Methods Multitasking Machine Reduces Cycle Times

Modern Machine Shop

MAY 12, 2024

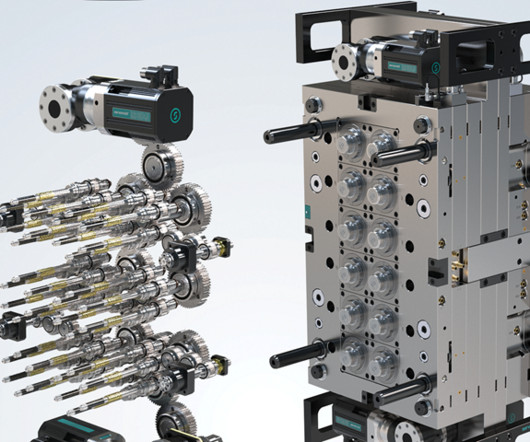

Source: Methods Machine Tools Inc. New AI-infused software releases, enhanced multi-processing features and faster simultaneous operations reduce cycle time up to 30%. Methods Machine Tools Inc. has released the Nakamura-Tome WY-100V to the U.S.

Let's personalize your content