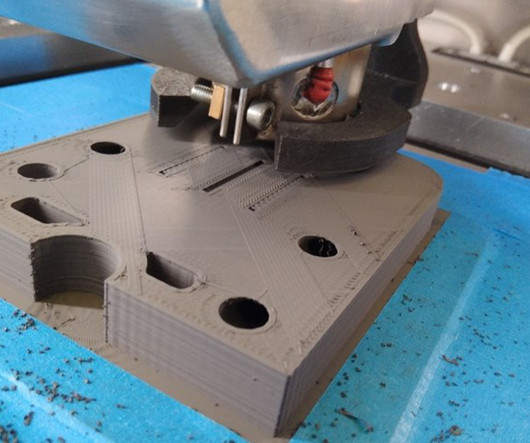

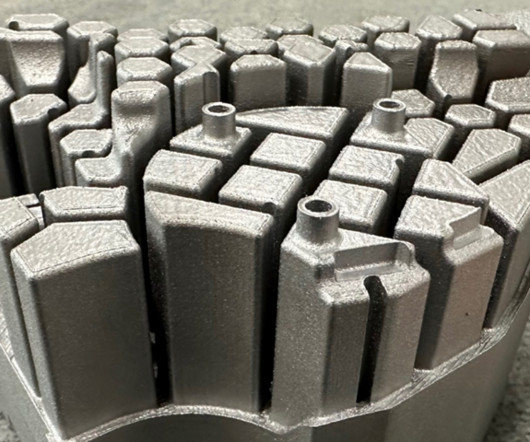

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Modern Machine Shop

MAY 12, 2024

Now, APG’s sister company uses 3D printed jaws more optimized to this process. One of the first applications the company found for metal 3D printing has proven to be a valuable business opportunity, both for serving internal needs of its sister machining business and now, those of outside customers as well.

Let's personalize your content